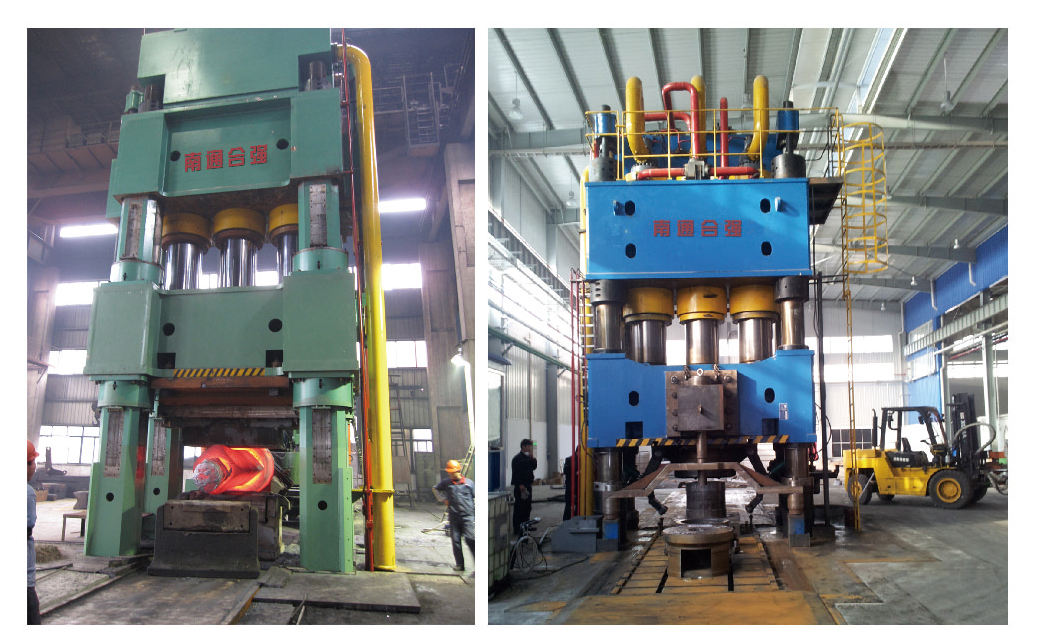

YH13 Series Free Forging Hydraulic Press

Scope of application:

This series of presses are mainly suitable for forging forming processes of various metal materials such as blanking, pier roughing, drawing, punching and reaming, finishing, and bending.

Performance characteristics:

The host structure has two structural forms to choose from: the three-beam and four-column structure is adopted, the operation space is spacious, the maintenance is simple, and the appearance is beautiful. The frame structure is combined. The slider is guided by a 16-sided adjustable mechanism with high precision and good rigidity. Strong anti-eccentric load capability.

The fuselage structure has been optimized by computer three-dimensional design and finite element analysis, and has sufficient strength and rigidity.

The machine has an independent hydraulic system and electrical control system. The hydraulic system adopts a specially designed high-flow fast forging integrated valve group with pressure grading control, which can meet a variety of free forging process requirements. The pressure rises and releases quickly and is flexible, which improves the forging efficiency and frequency, and reduces impact and vibration. The working pressure and working stroke can be adjusted according to the process requirements within the parameter range.

The electrical system adopts PLC control, the touch screen displays the working status of the machine, and the operation is convenient, and the action is sensitive and reliable.

This series of presses are designed with corresponding devices for users to choose according to different technological requirements. It can also be linked with the forging manipulator to realize the mechanization and automation of forging.

Optional parts and accessories:

Mobile workbench

Mold clamping device

Upper anvil shift device

Lower anvil displacement device

Up and down anvil

Workpiece centering and lifting device

Rotating Robot

Refrigeration oil cooler

Servo Motor Pump Unit

Workplace Monitoring System

Technical parameter:

| Project | Unit | YH13-800 |

YH13-1600 |

YH13-2000 |

YH13-2500 |

YH13-3150 |

|

| Nominal force | kN |

8000 |

16000 |

20000 |

25000 |

31500 |

|

| Return force | kN |

750 |

1250 |

1600 |

1600 |

3000 |

|

| Pressure classification |

一 |

二(800/1600) |

三(1000/2000) |

三(830/1660/2500) |

三(1050/2100/3150) |

||

| Work location |

二 |

三 |

三 |

三 |

三 |

||

| Maximum working pressure of liquid | MPa |

25 |

25 |

25 |

25 |

21 |

|

| Maximum stroke of slider | mm |

1200 |

1400 |

1500 |

1300 |

2200 |

|

| Opening |

mm |

2400 |

2500 |

2800 |

2300 |

4300 |

|

| Maximum travel of mobile station | mm |

1800 |

2500 |

4000 |

4000 |

6000 |

|

| Moving cylinder force | kN | 500 | 500 | 800 | 800 | 800 | |

| Moving speed of mobile worktable | mm/s | 200 | 200 | 200 | 250 | 200 | |

| Slide stroke speed | Hurry down | mm/s |

350 |

350 |

350 |

350 |

350 |

| Slow down | mm/s |

50 |

50 |

50 |

50 |

75 |

|

| Return trip | mm/s |

350 |

350 |

350 |

350 |

350 |

|

| Effective area of mobile worktable | About | mm |

3500 |

4000 |

6000 |

5500 |

8000 |

| Before and after | mm |

1350 |

1200 |

1800 |

1800 |

2000 |

|

| Column center distance | About | mm |

1600 |

2400 |

3080 |

3250 |

2850 |

| Before and after |

mm |

1400 |

1500 |

1470 |

2000 |

3000 |

|

| Height of mobile station from ground | mm | 0 | 0 | 0 | 0 | 0 | |

| Main motor power | kw |

110*4 |

110*8 |

110*10 |

110*14 |

160*20 |

|

| Project | Unit | YH13-4000 |

YH13-5000 |

YH13-6300 |

YH13-8000 | |

| Nominal force | kN |

40000 |

50000 |

63000 |

80000 |

|

| Return force | kN |

3500 |

4000 |

4000 |

6300 |

|

| Pressure classification |

三(1300/2600/4000) |

二(1650/3300/5000) |

三(2100/4200/6300) |

三(2700/5400/8000) |

||

| Work location |

三 |

三 |

2100/4000/6300 |

2700/5400/8000 |

||

| Maximum working pressure of liquid | MPa |

26 |

25 |

26 |

26 |

|

| Maximum stroke of slider | mm |

2200 |

2500 |

2500 |

2800 |

|

| Opening |

mm |

4300 |

5200 |

5000 |

5500 |

|

| Maximum travel of mobile station | mm |

6000 |

7000 |

7000 |

7000 |

|

| Moving cylinder force | kN | 1750 | 2000 | 3150 | 3150 | |

| Moving speed of mobile worktable | mm/s | 200 | 200 | 200 | 200 | |

| Slide stroke speed | Hurry down | mm/s |

350 |

300 |

300 |

300 |

| Slow down | mm/s |

75 |

60 |

50 |

50 |

|

| Return trip | mm/s |

350 |

300 |

300 |

3150 |

|

| Effective area of mobile worktable | About | mm |

8000 |

8000 |

9000 |

10000 |

| Before and after | mm |

2000 |

3000 |

3200 |

3200 |

|

| Column center distance | About | mm |

2850 |

3780 |

4500 |

5000 |

| Before and after |

mm |

3000 |

3000 |

3000 |

3200 |

|

| Height of mobile station from ground | mm | 0 | 0 | 0 | 0 | |

| Main motor power | kw |

160*20 |

160*20 |

160*20 |

160*26 |

|

More exciting is waiting for you!

Add:Group 1, Wenfeng Village, Baipu Town, Rugao City

Tel:86-513-87876288

Fax:86-513-87876266

Sales Hotline:86-18020196688

E-mail:hq@nthqkj.com

Web:www.nthqkj.com

Copyright © 2020 Nantong Heqiang Hydraulic Technology Co., Ltd. 苏ICP备14035421号