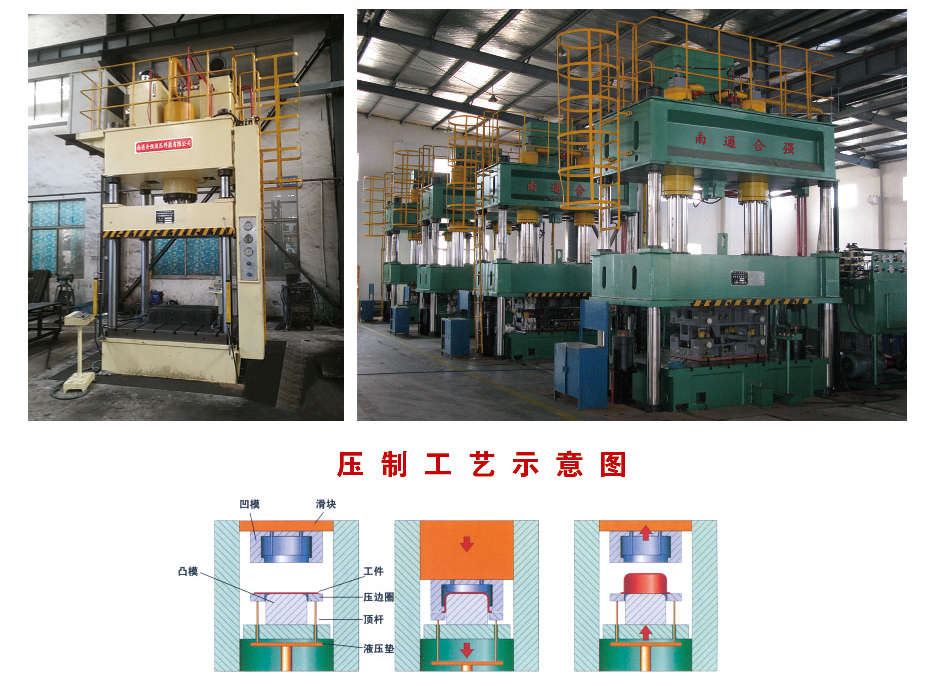

YH27 Series Four-column Single-action Hydraulic Sheet Metal Drawing Press

Scope of application:

This series of hydraulic press is mainly applicable to stamping processes like drawing, bending, shaping, squeezing and blanking, upturning of metal sheet components.

Performance characteristics:

Three-beam and four-column type. Large operating space, easy to maintain, gracefully shaped;

The machine consists of the machine body, the hydraulic system and the electrical control system. According to finite element analysis of computer, it has sufficient strength and rigidity, highly reliable, economic and practical.

The hydraulic system adopts the large-flow cartridge valve integrated system and oil-fluid precision filter. With reasonable layout and compact structure, it can deliver reliable moves and a long service life. Oil pipes are connected by the combination of high pressure rigid pipes and flexible pipes. The flange-type structure is preferred with less hydraulic impact force, which avoids oil leakage efficiently. The hydraulic system is equipped with water-chilling device. Equip locking device for dead spot of slider to ensure the safety of workers for mould repairing. The electrical system adopts the operating button for centralized control which has three modes of adjustment, manual and semi-automatic. Hydraulic die cushion can be set as jacking, not jacking and stretching. For each mode, both processes of fixed pressure and fixed distance can be completed.

Optional parts and accessories:

Multiform movable working tables

Adjustable hydraulic die cushion guide rail

Blanking buffer device

Photo-electric safety device

Ratio control system

Refrigeration-type oil cooler

Host system

Knock-out device

Servo motor pumps

Inlet ball valve and pilot valve

Technical parameter

| Project | Unit | YH27-200 |

YH27-315 |

YH27-315A |

YH27-400 |

YH27-500 |

YH27-500A |

YH27-630 |

YH27-630A |

|

| Nominal force | kN | 2000 |

3150 |

3150 |

4000 |

5000 |

5000 |

6300 |

6300 |

|

| Return force | kN | 240 |

300 |

400 |

480 |

550 |

1000 |

600 |

600 |

|

| Ejection force | kN | 400 |

630 |

1250 |

2000 |

2000 |

1600 |

2000 |

2000 |

|

| Retraction force | kN | 180 |

250 |

110 |

630 |

630 |

315 |

630 |

630 |

|

| Maximum working pressure of liquid | Mpa | 25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

| Maximum stroke of slider | mm | 800 |

800 |

800 |

900 |

1000 |

900 |

900 |

900 |

|

| Hydraulic cushion stroke | mm | 250 |

250 |

300 |

300 |

300 |

400 |

250 |

250 |

|

| Maximum distance between slider and worktable | mm | 1000 |

1250 |

1300 |

1400 |

1500 |

1500 |

1500 |

1500 |

|

| Slide stroke speed | Hurry down | mm/s | 180 |

180 |

200 |

200 |

250 |

120 |

250 |

250 |

| Slow down | mm/s | 6-12 |

6-12 |

10-25 |

10-30 |

8-25 |

6-15 |

12-30 |

12-30 |

|

| Return trip | mm/s | 100 |

120 |

180 |

180 |

220 |

80 |

250 |

250 |

|

| Hydraulic cushion stroke speed | Eject | mm/s | 65 |

55 |

85 |

65 |

65 |

50 |

55 |

55 |

| Return | mm/s | 95 |

100 |

160 |

100 |

100 |

160 |

150 |

150 |

|

| Effective area of mobile (auxiliary) workbench | About | mm | 1000 |

1250 |

2200 |

2400 |

2400 |

2000 |

2400 |

2800 |

| Before and after | mm | 900 |

1120 |

1400 |

1600 |

1600 |

1400 |

1600 |

1800 |

|

| Effective area of hydraulic cushion | About | mm | 600 | 800 | 1420 | 1720 | 1720 | 1200 | 1720 | 2020 |

| Before and after | mm | 600 | 800 | 800 | 1100 | 1100 | 970 | 1100 | 1100 | |

| Main motor power | kw | 15 |

22 |

37 |

55 |

55 |

45 |

90 |

90 |

|

| Project | Unit | YH27-630B |

YH27-800 |

YH27-800A |

YH27-1000 |

YH27-1000A |

YH27-1250 |

YH27-1600 |

YH27-2000 |

|

| Nominal force | kN |

6300 |

8000 |

8000 |

10000 |

10000 |

12500 |

16000 |

20000 |

|

| Return force | kN |

600 |

1000 |

1000 |

1150 |

1000 |

1300 |

1700 |

2500 |

|

| Ejection force | kN |

2000 |

2500 |

2500 |

2500 |

3000 |

4000 |

5000 |

6300 |

|

| Retraction force | kN |

630 |

630 |

630 |

630 |

380 |

380 |

380 |

380 |

|

| Maximum working pressure of liquid | Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

| Maximum stroke of slider | mm |

900 |

1000 |

1200 |

1000 |

1200 |

1200 |

1400 |

1400 |

|

| Hydraulic cushion stroke | mm |

250 |

350 |

350 |

400 |

400 |

400 |

450 |

450 |

|

| Maximum distance between slider and worktable | mm |

1500 |

1600 |

1800 |

1600 |

1800 |

1800 |

2000 |

2200 |

|

| Slide stroke speed | Hurry down | mm/s |

250 |

250-300 |

250-300 |

250-300 |

250-300 |

250-300 |

250-300 |

250-300 |

| Slow down | mm/s |

12-30 |

8-16 |

10-25 |

8-20 |

12-30 |

12-30 |

10-25 |

12-30 |

|

| Return trip | mm/s |

250 |

120 |

120 |

180 |

250 |

250 |

220 |

250 |

|

| Hydraulic cushion stroke speed | Eject | mm/s |

55 |

65 |

90 |

70 |

90 |

90 |

90 |

90 |

| Return | mm/s |

150 |

160 |

160 |

160 |

160 |

160 |

160 |

160 |

|

| Effective area of mobile (auxiliary) workbench | About | mm |

3200 |

3000 |

3600 |

3200 |

4000 |

4000 |

4600 |

5000 |

| Before and after | mm |

2000 |

1800 |

2200 |

1800 |

2200 |

2500 |

2500 |

2500 |

|

| Effective area of hydraulic cushion | About | mm |

2320 |

2320 |

2900 |

2320 |

3220 |

3220 |

3750 |

4150 |

| Before and after | mm |

1420 |

1120 |

1700 |

1120 |

1700 |

1720 |

1750 |

1750 |

|

| Main motor power | kw |

90 |

74 |

90 |

90 |

135 |

180 |

180 |

270 |

|

More exciting is waiting for you!

Add:Group 1, Wenfeng Village, Baipu Town, Rugao City

Tel:86-513-87876288

Fax:86-513-87876266

Sales Hotline:86-18020196688

E-mail:hq@nthqkj.com

Web:www.nthqkj.com

Copyright © 2020 Nantong Heqiang Hydraulic Technology Co., Ltd. 苏ICP备14035421号